Search

Vision 2030 Drives Growth

The compaction equipment industry in India has witnessed significant technological advancements in recent years. Manufacturers are integrating advanced features, such as GPS technology and telematics, into their machines to enhance precision and efficiency.

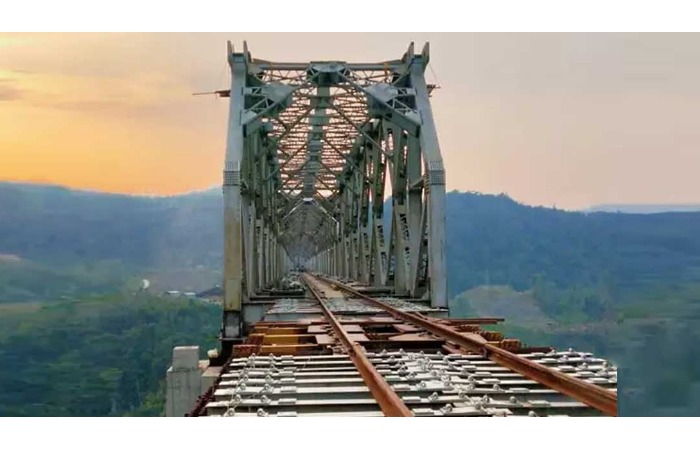

No Bumps in the Road

India has been investing significantly in infrastructure development, including the construction of roads, highways, and expressways. This investment has driven the demand for road construction equipment.

Poised for growth

As coal mining activity escalates, the need for tipper trucks will rise.

Zinc: Securing a Sustainable Future for Mining Industry

The steel used for the coaches of the Vande Bharat trains has been fortified with zinc.

Modern Demolition

Increased efficiency, increased safety and reduced need for skilled labour are among the many factors that drive the development of autonomous construction equipment.

The Mining Boom

India's increasing coal projects drive a surge in mining equipment demand!

Technology penetration in mine planning is still lower in India

Arun Misra, CEO, Hindustan Zinc, speaks on the challenges facing in the mining equipment market in India, and the ways to address them.

Going forward, digital technology will play a key role

Deepak Shetty, CEO and Managing Director, JCB India, speaks on the key demand drivers for backhoe loaders in India, and its dealership and product service

Going forward, digital technology will play a key role

Deepak Shetty, CEO and Managing Director, JCB India, speaks on the key demand drivers for backhoe loaders in India, and its dealership and product service.

Demand for locally-manufactured bearings has been rising

Sujeeth Pai, Director, Industrial Business, SKF India, speaks on the company’s approach to innovation and product development.

L&T Finance launches Warehouse Receipt Financing

L&T Finance (LTF), a subsidiary of L&T Finance Holdings and one of the leading non-banking financial companies, has launched Warehouse Receipt Financing (WRF), a first-of-its-kind digitally assisted journey for loan facilities against agri-commodities

Entering an era of transformation

Off-the-road tyre manufacturers and suppliers are facing brand-new difficulties as a result of technological advancements and evolving end-user needs that are pushing the market into uncharted terrain.

L&T Finance launches Warehouse Receipt Financing

Launch of Warehouse Receipt Financing in a digitally-assisted journey for the first time in India

Bringing sustainability to the fore

JCB has continued to make concerted efforts to conserve and optimise the use of energy.

Escorts Kubota's Q3 standalone profit doubled to Rs 186.4 cr

Revenue from operations was at Rs 2,263.7 crore in quarter ended December 2022 as against Rs 1,971.5 crore in corresponding quarter of the previous fiscal.

Creating Compact Foundations

The upward trend of mechanisation in the construction and road-building industries is expected to drive the compaction equipment market in India.

Going forward, we will have new products

Kaushik Sen, Country General Manager, Drillman Global, speaks on the IoT and digital technologies that are evolving in the business.

Escorts Kubota Q2 standalone net profit at Rs 87.7 cr

Q2 standalone profit before exceptional items and tax at Rs 191.5 cr.

Country Roads Take Me Home

The slowdown in the road construction activity has been a drag for the construction equipment sector.

Escorts Kubota Q1 profit at Rs 147.5 cr

Escorts Kubota reported a net profit of Rs 147.5 crore in the quarter ended June 30, 2022, as against a profit of Rs 185.2 crore in the corresponding quarter of the previous fiscal.

Forging and components industry to experience 60% decline due to electric vehicles: AIFI

The Association of Indian Forging Industry (AIFI) has witnessed a challenging time in the first half of 2022 as a result of increased input costs, particularly steel, aluminum, and nickel prices.

Auto component sector sees record turnover of Rs 4.2 trillion in FY22: ACMA

Indian auto components industry clocked its highest-ever turnover of Rs 4.2 trillion in 2021-22, registering a growth of 23 per cent on the back of strong performance in exports

Components industry to witness 60% decline due to EVs: AIFI President

AIFI has expressed concerns to the government over high steel, aluminum, and nickel prices, as the increase in steel prices has damaged the Indian forging industry

Forging and components industry to experience 60% decline due to electric vehicles: AIFI

• The increase in steel, aluminium, and nickel prices have hammered the industry in India

Escorts Kubota Q1 profit at Rs 147.5 cr

Construction equipment volumes up by 59.4% at 966 units

Overall, the market scenario in India looks promising

Excon has always been a confluence of construction equipment ecosystem members like equipment and component manufacturers, customers, financiers, equipment dealers and policy makers.

The market scenario in India looks promising

Dheeraj Panda Chief Operating Officer (Sales, Marketing and Customer Support) Sany Heavy Industry India.

Rise in steel and commodity prices has increased input cost

Anand Sundaresan Managing Director, Ammann India

Indian auto component industry likely to grow 8-10% in FY23

According to rating agency Icra, the Indian auto component industry might have 8% to 10% growth in Financial Year (FY) 2023, due to the easing of supply-chain issues along with commodity inflation in the next half of the year.

Electric mobility is the segment we focus on most

Kessler, as the name suggests, has a long history just as any other German /European company, and is being run by the third-generation family and closely linked with the southern German region.

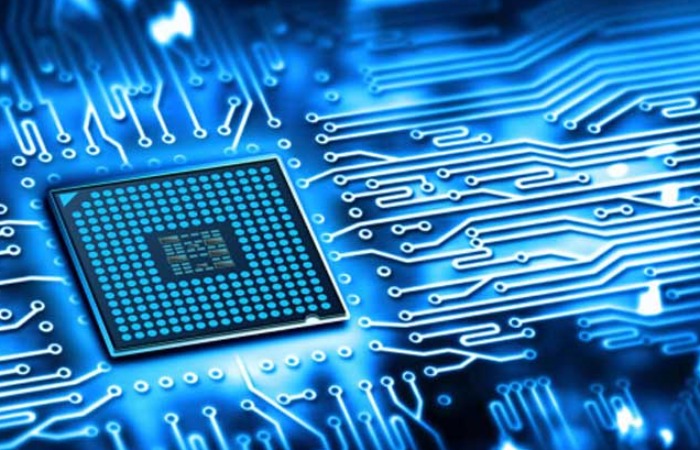

Semiconductor shortage to hamper ce industry

Global semiconductor shortages may curtail new equipment production,resulting in higher used equipment prices.

Opportunities galore

The construction industry across the globe is anticipated to present significant opportunities for construction equipment.

We are trying to scan India For our global model

Kessler, as the name suggests, has a long history just as any other German /European company, and is being run by the third-generation family and closely linked with the southern German region.

Snapshot of L&T's Q3FY2021-22 results

Larsen & Toubro Q3 consolidated revenue recorded growth of 11% at Rs 39,563 cr

Icra slashes growth forecast for auto components industry to 17-20 pc for FY22

According to Icra, the components industry is now expected to grow at 17-20 per cent in 2021-22, partly aided by "the low base of last year and commodity passthrough" besides growth driven by domestic OEM, replacement and export volumes.

7th India Construction Festival

Organised by the FIRST Construction Council in Mumbai on October 22, the event successfully brought together the who’s who of the infrastructure and construction industry.

Escorts Q1 results FY22: Net profit at 185.2 cr

Tractor manufacturing major Escorts recorded a two-fold jump in net profit during the quarter ended June 2021. The firm posted a 101 per cent increase in standalone net profit at Rs 185.2 crore against Rs 92.2 crore in the previous year.

Escorts Q1 results FY22: Net profit at 185.2 cr

Tractor manufacturing major Escorts recorded a two-fold jump in net profit during the quarter ended June 2021.

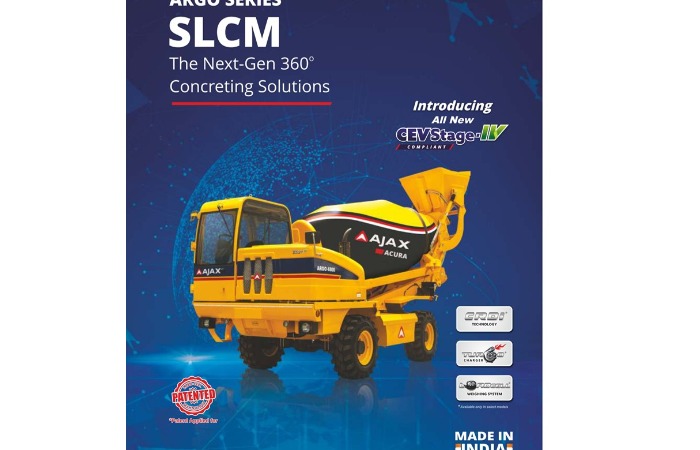

AJAX introduces the ‘All new CEV Stage-IV’ compliant ARGOs

These engines are more environment friendly with well proven CRDi technology and After Treatment System (ATS) that reduces emission levels.

Larsen and Toubro achieved consolidated revenues of Rs 29,335 crore

Larsen and Toubro achieved consolidated revenues of Rs 29,335 crore for the quarter

In 2022, the market for hydraulic excavators may touch 25,000 units

Last year, the excavator market touched 18,000 units. The start of last year was good. Later on the numbers dipped due to Covid-19 pandemic. However from September onwards, the market picked up.

We expect the demand to grow for hydraulic excavators

Arvind K Garg, Executive Vice-President and Head-Construction & Mining Machinery Business, Larsen & Toubro

Demand diversity in CE sector

Infrastructure is a silver lining in the pandemic for many States. With the lockdowns in place in most States during 2020 and reduced vehicle traffic, crews continued their road work and were getting more work done than usual.

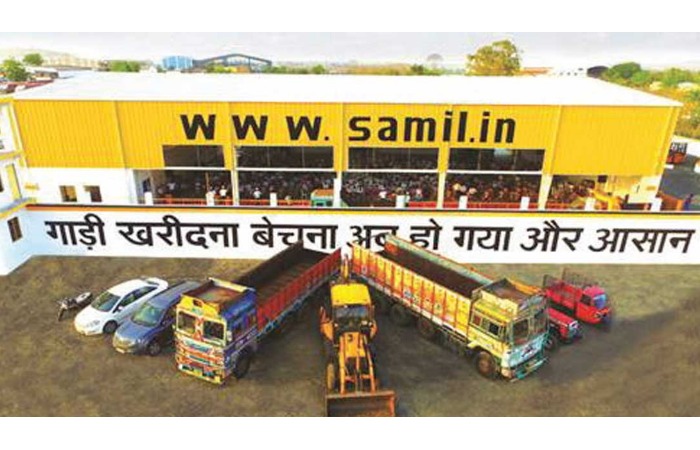

Shriram Automall – the Power of Choice for Construction Equipment

Shriram Automall India (SAMIL), an ISO 9001:2015 certified company, is India’s first-ever service provider to offer a well-organised and transparent platform for the exchange of pre-owned vehicles and equipment.

project44 acquires Ocean Insights

World’s leading ocean visibility solution joins forces with the largest over-the-road network to rede?ne the value of end-to-end supply chain visibility

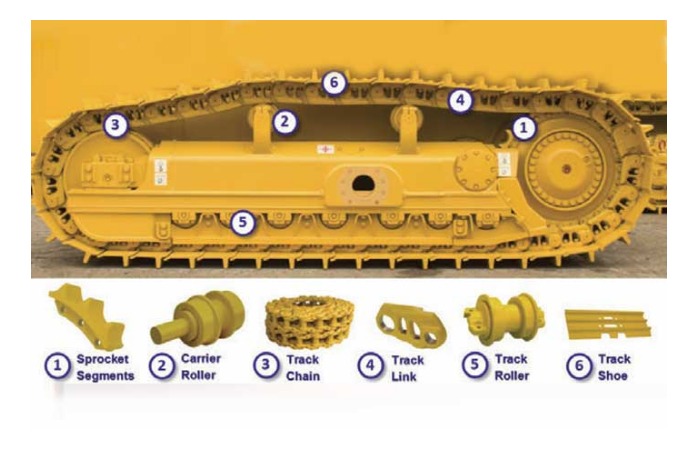

New Avenues to Growth

The ongoing COVID-19 pandemic has hit market players adversely on the supply side, causing declining sales of undercarriage components.

Mining market scenario

The upcoming mining reforms are expected to drive the demand for advanced mining equipment technologies and solutions.

Our growth is in double digits

AxleTech is a manufacturer of axles to speciality applications in off-highway and defence segments.

Cash flow is paramount for sustaining equipment market growth

Sunbeam Infra Equipments (A Division of Sunbeam Generators) launched a trailer concrete pump of 50 cu m per hour capacity and mixer pump at bauma this year.

Siemens provides digital solution to Chinese mining group

To increase outputs while reducing shutdown times, YanZhou Coal Mine Co is for the first time establishing a cloud concept for mine hoist, enabling it to centrally monitor production, analyse, and respond to insights from real-time data.

Pushing Boundaries

With the demand for excavators growing in the market, OEMs are introducing new features to further improve the efficiency and productivity of the machines, helping in quick and qualitative project execution.

Revival on Cards?

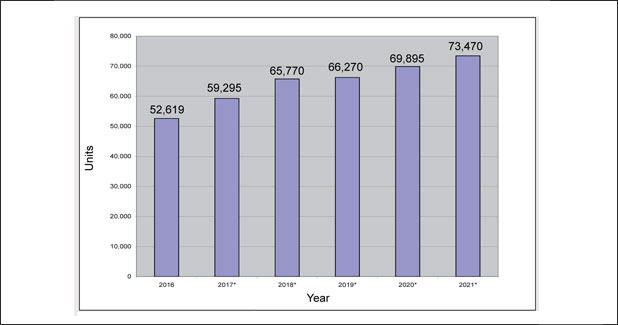

India is witnessing an improved growth trend in coal mining, as Coal India Ltd (CIL) is aiming an output of one billion tonne by 2020. CIL has earmarked a capital investment of Rs 57,000 crore, as part of the road map for one billion tonne target, with a planned capex of Rs 8,500 crore in 2017-18.

Escorts posts over 91 per cent profit growth

Escorts reported a profit of Rs 160.4 crore in the year ended March 2017, up by 91.6 per cent as against a profit of Rs 83.2 crore in the previous fiscal. During the period, tractor sales were up by 24 per cent at 63,786 tractors as against 51,455 tractors in the previous fiscal. Construction equipment volume went up by 29.6 per cent at 3,315 units as against 2,555 units in the previous fiscal.

Back on Growth Path

Global sales of construction equipment are expected to increase seven per cent this year, according to updated forecasts from specialist market intelligence company, Off-Highway Research.

Emerging market trends

Indian Oil Corporation (IOC) Karnataka state office conducted an All India Servo Auto OEM meet in Bengaluru recently. With the theme 'Driving the Xtra Mile', the meet was aimed at sharing and deliberating the latest developments in emission norms, fuel technology, lubricant technology, greener fuels, vehicle technology and after treatment devices. The purpose of this programme was to strengthen relationship with valued customers and other stake holders and to position Servo as one-stop solution

Canada to be bauma 2019 partner country

Messe M?nchen and the Verband Deutscher Maschinen- und Anlagenbau (VDMA?German Engineering Federation) have agreed for Canada as partner country at bauma 2019.

Canada to be bauma 2019 partner country

Messe M?nchen and the Verband Deutscher Maschinen- und Anlagenbau (VDMA?German Engineering Federation) have agreed for Canada as partner country at bauma 2019. Klaus Dittrich, Chairman and CEO, Messe M?nchen, said of the choice of Canada as a partner country: ?In selecting Canada, we were not just selecting a very stable sales market but an attractive and dynamic one as well.

Control technologies for Productivity

Machine control technology helps the operator do the job in real-time basis with accurate information of job specification from data in the cabin monitor. This leads to savings in both, project costs and time, as faster completion of tasks translates into less fuel required for the job.

We are extremely bullish on OTR segment from a long-term perspective

Historically speaking, specialty definition for us is OTR tyres for both India and international markets, while for agriculture, it is only international. Indian agriculture is not treated as part of specialty business, for various reasons. We came out with our first specialty tyre in early 1980s starting with the port segment.

Global CE Market to Improve

Global sales of construction equipment (CE) are forecast to grow 3.9 per cent in unit terms in 2016, to 760,508 machines, according to specialist economic forecasting and market research consultant, Off-Highway Research.

Pick-n-Carry Hydra: Bestseller

As the Numero Uno bestselling lift and reach product, Hydra crane still continues to be the most demanding mobile crane category in India. Tyre-mounted articulated steering, hydraulic mobile pick-and-carry crane, colloquially termed ?Hydra?, was introduced in India

Large Miners Forward

While the global mining industry is on the decline, India is witnessing a reverse trend. Many international mining equipment manufacturers are showcasing their products at BAUMA 2016, Germany, in a big way, at a time when Coal India

Availability and utilisation achieved are key performance indicators for large mining equipment.

We have seen increase in enquires for large mining equipment segment in India in the last six months. Public Sector Units (PSUs) contribute to most of the increase in enquiry. From private miners, contractors or mine developer-operators (MDOs)

Bosch posts 5.7 per cent growth in net sales, income

Bosch posted net sales and income from operations of Rs 2,598 crore in Q2 of the financial year 2015-16, registering a 5.7 per cent increase over the comparable period of the previous year.

This year we expect to sell about 300 machines

We have been associated with Escorts for the past 25 years, starting with Escorts cranes representing them in Tamil Nadu and Kerala. Later we expanded our business to backhoe loaders, forklifts and road compactors. Now we deal in the full range of Escorts construction equipment in these two states.

Gearing Up

The gear manufacturing industry in India is set to continue to rise at a CAGR of 9.6 per cent for the 2012-2016 period Gears are used for transmitting power from one part of a machine to another. It helps in variation of speed, force and direction in a machine.

Is the money flowing again?

Tricky times call for strong strategies but the long term prospects are bright for financiers with staying capacity, finds Charu Bahri. Demand for construction equipment finance has been down for the last few years.

Essel Group Inks Technology Transfer Pact with Three German Firms for Smart cities and Green Energy Projects in India

The Essel Group, one of India?s largest business conglomerates and a front runner in developing the Smart City Framework for India, has recently entered into technology transfer pacts with three leading German firms during its participation at the world?s largest trade fair Hannover Messe 2015 in Germany.

M-Sand as Alternative for Natural Sand

With the latest innovations in crushing technology, modern crushers can produce well-graded and high quality sand, writes Ramanan Anantharaman.

New Expectations

The new government has just sworn in at the Centre, driving new hopes in the industry. DK Vyas pens down the wish list of expectations from the new government.With the National Democratic Alliance (NDA) having formed the government, industry expectations are high that the new Prime Minister (PM) will be able to lead the economy out of the low growth era through decisive governance.

Expectations from the New Government

Devendra Kumar Vyas, Chief Executive Officer at SREI BNP Paribas pens down the wish list of expectations from the new government. With the National Democratic Alliance (NDA) having formed the government, industry expectations are high that the new Prime Minister will be able to lead the economy out of the low growth era through decisive governance.

The crack of dawn

The recent decision of the Supreme Court lifting the ban on iron ore mining in Goa has implications beyond this state as the mining sector's woes have added to the economic slowdown along with low growth in manufacturing. Over the past two years, due to the ban on iron ore mining in Goa, Karnataka and Odisha, the iron ore export fell by 85 per cent or 100 MT and as a result, India, once the world?s third-largest exporter, turned a net importer of the commodity in recent times. The closure of iro

38 German companies will showcase their innovative products at Excon 2013.

German investors in India take a positive long-term view of the Indian market and continue to invest in their operations and tap growth opportunities. . Maharashtra, with around 39 per cent share of German investments, remains the most attractive destination for German business in India.

Hind Copper to upgrade machinery

Hindustan Copper is planning to replace its old equipment at some of its underground and open cast mines this fiscal as ore production was hampered last fiscal. The company in its latest annual report, said that "since majority of Khetri Copper Complex

India may pip China in coal import volume

India, which is presently the second largest importer of coal, may pip China to become the largest importer of the commodity in the next 3-5 years. This was predicted by James O?Connell, Editor-in-Chief for coal in Platts McGraw Hill Financial. O?Connell said Indonesia is likely to remain one of the top exporters of the com

Aluminium is the fastest growing nonferrous metal

According to an industry research, aluminium is the fastest growing nonferrous metal and its production volume is next only to steel in India. By 2017, the demand and consumption of aluminium may rise to about 3 million tonne from nearly 1.71 million tonne now. By 2030, aluminium consumption growth will be driven by China and India, repo

ICVL identifies 5 overseas assets

CS Verma, Joint Chairman of Steel Authority of India (SAIL) informed that ICVL has identified at least four or five good coking coal mines in Australia, the US and Mozambique for acquisition. International Coal Ventures (ICVL), a consortium led by SAIL, is conducting due diligence on these assets. It may be recalled that ICVL was formed in 2009 by public sector firms like NTPC, Coal India, NMDC and Rash

Coal India increases coal prices

Coal India has rejigged coal prices from May 28, resulting in a weighted average increase of about 5 per cent. The company has cut prices of some high-grade coals and hiked prices of lower grades, including an almost 50 per cent hike in the prices of output of a particular mine dedicated to NTPC, Coal India chairman Narsing Rao said.

India's rank improves in Fraser mining survey

According to a survey of the world's leading nations in mining sector conducted by a Canadian-based free-market think-tank Fraser Institute, India was ranked 81st from 89th spot last year. China's ranking declined to 72nd out of 96 in 2012-13 from 58th out of 93 the prior year. The survey measures the overall policy attra

Auto industry demands excise duty cut

The Indian automobile industry, faced with declining sales in the current fiscal due to high interest rates, rising fuel costs and commodity prices, is seeking an excise duty

The CE market is set to grow to over 100,000 units by 2016

The cumulative sales of backhoe loaders, crawler excavators and wheeled loaders have been growing at a CAGR of over 20 per cent for the last ten years and will continue to grow at an impressive rate.

We aim to increase asset size by 65 per cent over the previous year

Fastest response time, large distribution and collection net?work coupled with high risk appetite and complete geographic, customer and asset classes' inclusion gives as an edge over competition in retail segment financing, says Pratap Paode, Chief Executive Officer, SEFC.

Steadily chugging ahead

Even though the road sector in India continues to face multiple challenges, a strong pipeline of projects supports long term prospects. Around $180 billion investment is earmarked for the road sector, which is the highest ever investment for any Five Year Plan, and this should have a very positive impact on the construction equipment industry. The prime factor favouring the growth of the road equipment industry is the sheer scale of work still to be done in this sector.

Our highest priority is quality for....

What makes NKE different is our service, soft factssuch as customer proximity, flexibi?lity, technical competence and inno?vativeness, says Jasvinder Singh Bhatia, Sales Director ? India/Bangladesh/Sri Lanka, NKE Austria. Excerpts from the interview.

Sandvik offers the lowest power consumption in VSI crushing

At Sandvik, we also give utmost importance to continuous inno?vation; innovation is seen mostly in terms of continuous mecha?nisation, electronics, enhanced produ?ctivity, lower energy consumption, etc. that contribute to our customers? productivity,

JCB gives utmost importance to safety and our tracked excavators are the safest choice

All JCB excavators are fitted with a unique filtration system which increases hydraulic oil and filter life resulting in huge cost savings and better emissions.

The Big Ones Get Better

Sales of crawler excavators, which grew until 2008, declined by 20 per cent in 2009 but recovered strongly to 11,453 units in 2010, a growth of 44 per cent.

JCB always keeps customers at the heart of everything it does

?We focus on both process innovation as well as product innovation. We have dedicated teams working on each of our product lines with the sole purpose of increasing efficiency through value engineering," says Vipin Sondhi, Managing Director & Chief Executive Officer, JCB India.

Is the growth story sustainable?

It is crystal clear, to reach world-class levels, infrastructure needs a tremendous boost for the next several years; this will augur well for the CE sector where most of the major players continue to upgrade capacity and widen product lines.

X factor drives growth

At under 60,000 units of CE, the industry?s contribution to the auto component industry, at nearly $40 billion for 2010-11, is still very insignificant considering a tractor production of over 5,25,000 units and medium and heavy commercial vehicles over 3,30,000 units.

Bright Future

German mining equipment manufacturers set for record sales. German mining equipment manu?facturers expect a sales of almost EUR 5 billion, representing a 32 per cent sales growth for 2011.

CE sector on cusp of boom

Infrastructure spending will drive construction equipment (CE) growth. As per the 12th Five Year Plan estimates released, the following is the spending envisaged:

India is a key market, and we are strongly committed to its growth

Based on our 10 year plan, by 2020 we hope to be able to secure about five per cent of the whole construction equipment market share in India which comes up to half a billion US dollars. That is our target and we hope that we can progressively move towards that. 1 - -

22720 14 102 2011-12-01 00:00:00.000 Agith G Antony Racing Ahead The Indian CE section, at present the fifth largest CE market in the world, is tipped to become the second largest CE market by 2015, and by value terms, to reach 15 billion by 2015, and a whooping 20 billion by 2020. The ongoing race to stand tall and deliver is slowly but steadily changing the rules of the game. Agith G Antony trains his gaze on the changing CE horizon.

Ask any of the global OEMs who have set up shop here long ago or in the last couple of years, or for that matter, eask any new entrant how they perceive the potential of the Indian market. Their response is invariably couched in cliches: 'India is a key market and if you are not in India, there is something amiss with your business strategy.' Truth to tell, that response reveals the track on which the growing CE industry is heading.

"India is a key market and we are strongly committed to its growth," says Sew Chee Jhuen, President, Singapore Technologies Kinetics, which has recently forayed into the Indian CE market with the launch of a motorgrader. "For the new plant, we are pumping in around $15-20 million. Our total investment planned for next few years is $35 million. We are not limiting ourselves to this alone; we plan to build another factory very soon in India," he further adds.

At a recent press meet, Vipin Sondhi, Managing Director & CEO, JCB India stated, "We have no option as a country but to invest in infrastructure at all points in time." It is quite possible that the statement reflects what is in store for the construction equipment industry, and how OEMs are charting their business strategies to acquire a major share of the market.

The Prognos World Report, released way back in 1995, indicated that the classic industrial countries will only be contributing a third to worldwide growth by the year 2025, whereas, following the same timeline, the Indian economy was tipped to be a major catalyst stimulating international business growth. Today, India has emerged as one of the nations shaping world economy, a preferred investment destination and one of the world's most rapidly growing markets. Its national economy, its demographic structure and its high, sustained rate of growth has tagged India as the second most important market after China, coupled with the fact that contrary to China, domestic demand is already a strong development factor.

It's crystal clear: the role of India in the world economy has become so pivotal, certainly not because of the recent crisis, (though that must have accelerated matters, of course) but simply because of the huge potential India holds as a fast developing country. As per reports, the mid-term forecast for the next five years indicates that the gross domestic product in Europe and the US will grow at moderate annual rates while emerging markets such as China, India and Brazil are expected to maintain a much higher growth. The economic crisis, as well as the recovery after it, certainly had its impact in the global construction equipment market. For global OEMs with diversified enterprises, harsh impact in particular markets were largely offset by positive development in others. In fact, the total investment of many an OEM has gone up to considerably high levels again.

The dramatic shift in terms of sales of construction equipment from classic markets to BRIC nations is already evident as more global players are anchoring alongside the Indian shoreline. Over the last half decade, the number of global OEMs entering the Indian market has shot up; this includes major players from Japan, US, Germany, Korea, etc. On the other hand, domestic companies have also been either expanding their domestic capacities or diversifying their product portfolio. The result - with the emergence of new market players and expansion plans underway, the industry is expected to become more competitive and as a result, more fragmented.

Says DK Vyas, Chief Executive Officer, Srei BNP Paribas, "As per our estimates, the present organised equipment market for infrastructure and construction equipment (ICE) in India should be anything around Rs 24,000-28,000 crore ($4.7-5.5 billion). Thus, the construction equipment financing industry should be pegged at around 85 per cent of this figure. The growth of the ICE sector will be healthy. Our calculations tell us, when our GDP grows at 9 per cent annually, the annual growth rate of the ICE sector is at around 30 per cent. But in a worst case scenario, if the annual GDP growth rate even slows down to 6 per cent, the annual growth rate for ICE will be around 20 per cent. With such growth prospects, it is no wonder that global ICE majors are making a beeline to India and setting up shops here."

The construction equipment manufacturing industry estimates that CE demand will cross 100,000 units during 2014, whereas the contribution of the CE rental business, perceived to be another growth driver, is expected to double from the present seven to eight per cent of the size of the global industry to 16 per cent by 2015. Even though the industry spirit is currently dampened due to the volatility in oil and commodity prices and inflationary pressures, and to some extent, the alleged scams and corruption charges, the overall picture is quite positive and the sector is bound to see growth every year, propelled by government policies and support from the private sector.

As the rules of the game change, so do the trends. The increasing dominance of price-and-value focused customers, increasing awareness on the utility and versatility of specialised equipment, deeper engagement of global equipment manufacturers in India, increasing opportunities for exports and last, but not the least, the emission norms and greater emphasis on reducing the negative impact on environment, have been moulding the CE industry's trajectory onto a more responsible path as never before.

The emphasis today clearly is on creating capacity and backing it up with dealer networks and efficient service. As per sources , India will need an infusion of $1 trillion investment during the 12th Five Year Plan; there is no doubt though that the country has become one of the top priority markets for many global OEMs. A mere glance over the past five years' growth supports this fact.

As research inputs suggest, companies need to pursue four growth-enabling initiatives to expand the market. These include enhancing the quality, delivery and price of after sales services to increase share of service revenues from two per cent of total revenues to the global average of about eight per cent; addressing key gaps in financing to catalyse latent demand particularly in rural areas and small towns; expanding dealer and channel network coverage to address buyer fragmentation and quality, and proactively strengthening supplier capacities and capabilities.

The increasing competition from product imports from other low-cost countries that could potentially challenge the industry growth and the ever-increasing input costs have been a major challenge for the industry. To address these issues and achieve full potential in the market, OEMs have embarked on strategic initiatives: introducing India- specific products that includes low-priced multi-purpose equipment to attract new customers and to increase mechanisation in important areas; improving cost positions to better deal with the onslaught of competition from LCCs; and pioneering efforts to boost exports in areas like engineering and design services that leverage India's technical prowess.

Another perceptible shift is towards green procurement. Customers who rely on energy-efficient and environment-friendly machines will have an advantage over their competitors. The increasing fragmentation of the industry, with more players setting up production facilities for specialised machines, is an indicator of the industry going greener.

The Bharat Stage-IV norms are already in effect for automobiles and the BS-III is now in effect for most other segments except gensets; in all, it constitutes a major initiative to bring down the carbon footprint. One of the challenges faced by the manufacturers of diesel engines today is to develop products that will deliver higher performance, longer life, lower operating costs and at the same time, with less of an environmental impact. To comply with these standards, engine manufacturers have invested in the research and development of new, cutting-edge technologies aimed at taking diesel emissions levels to near zero. It's heartening to note that JCB has already launched the ecoMAX customised for Indian conditions and emission norms; Mahindra Navistar Engines will introduce a 4-cylinder engine to the Indian market for various genset and construction equipment; Cooper has moved up the value chain through a logical diversification in the engine and auto?motive manufacturing business and has launched a multipurpose, flexi-fuel, twin-cylinder engine, for which commercial production has already begun.

But on the flip side, the rising input costs and lack of a clear-cut road map for clean fuel are major deterrents. Another major challenge is to bring down the technology gap between the organised and unorganised segments. Ironically, while every other sector has been moving towards reducing emissions caused by engines, the genset industry has been largely inactive. There was even a move to extend the deadline for introducing the new norms for gensets. Thanks to the tireless efforts of some of the manufacturers, the deadline of 1 October 2013 stays effective and not only that, most of the manufacturers have already geared up for these new norms; some of them have already introduced their lower emission diesel engines into the market.

The point is, the unorganised sector neither has the resources nor the technology to develop such engines. Concerted efforts from the Central Pollution Control Board (CPCB), Delhi and the Association of Diesel Engine Manufacturers Association (IDEMA) and unorganised segments , could dramatically reduce the technology gap, thereby reducing emissions from diesel engines. With this in place, we can look forward to a cleaner and greener industry.

More importantly, more and more OEMs are charting different routes other than the classic ways of sales and service, to make it more holistic in terms of product offerings and relations with clients. Some leading OEMs have already started implementing the concept of MARC, though not to the fullest extent as it exists in the developed markets. Still, EI believes it's a good beginning.

A recently released report from the United Nations Industrial Development Organisation (UNIDO) forecasts that the world's manufacturing output growth will be slower this year, compared to the last year. As per the report, the developing countries have maintained high growth rates of manufacturing with production increasing by 11.1 per cent. For 2011, the MVA growth of industrialised countries is likely to be around 3.2 per cent, whereas that of developing countries is expected to grow by 8.4 per cent. Clearly, India and China are where the action is.

The role of India in the world economy has become so pivotal, certainly not because of the recent crisis, (though that must have accelerated matters, of course) but simply because of the huge potential India holds as a fast developing country.

We have doubled our distribution outlets over the last five years

With strategic investments in place, we have the right kind of facilities and can upscale our production whenever required, says Vipin Sondhi, Managing Director & CEO, JCB India,

Manitowoc Crane Care is a huge differentiator

We focus on cost of ownership for our customers and onsite productivity. That means high quality manufacturing, backed up with the best customer support to ensure our cranes can keep working at their optimum productivity for as long as possible,? says Prem Naithani, National Sales Manager, Mobile and Crawler Cranes, Manitowoc Cranes India.

We will launch CRDI technology-enabled engines for both automotive and nonautomotive applications.

With stateoftheart R&D centres in Italy, the US and India, we strive to give the very best in to the market in India and abroad. Our R&D is continuously working on development of compact, lightweight and fuel efficient engines,? says Sudipto Mukherjee, General Manager Marketing, Lombardini India. Excerpts from the interview. 0 - -

20041 14 102 2011-11-01 00:00:00.000 Behram Ardeshir An Engineering Marvel The first twin cylinder CRDI diesel engine launched in 2010, is an engineering marvel as it is compact, fuel efficient, powerful and is a flexi fuel engine that can run on diesel, CNG or LPG, writes Behram Ardeshir.

Cooper Corporation has a ninety year old pedigree. They have always relied on technology and innovation. In 1922, Cooper made India's first diesel engine. In 2010, they produced India's first twin cylinder, CRDI, Euro IV compliant diesel engine.Cooper Corporation, a leading manu?facturer of engine components like liners, crankshafts, blocks, heads etc for decades, have now decided to set up a state of the art engine manufacturing facility. This is the first Greenfield engine manufacturing facility, other than a small scale operation, to be set up in decades anywhere in the world.

Ricardo of UK was assigned the task of designing the family of engines. The first engine is India's first twin cylinder CRDI diesel engine. This engine was launched in 2010 and is an engineering marvel as it is compact, fuel-efficient, powerful and is a flexi fuel engine that can run on diesel, CNG or LPG.

Farrokh Cooper, Chairman of Cooper Corporation was very clear at the outset. He wanted an engine that incorporated the latest international technology and one that was protected for future legislation as well. Thus Ricardo designed an engine that was Euro IV compliant and Euro V-protected. It was compact and fuel-efficient but Cooper wasn't ready to stop there. He wanted an engine that would work in both vehicular and off-road applications. Going a step further, he wanted the same engine to run on both diesel and gas! Cost of development was not a major factor. The result was a world's first, a twin cylinder CRDI engine that ran on diesel and gas, and was useable on-road and off-road. To top that, it met with all international legislation both present and future, it was compact and more efficient than most of its competition! Whilst most of the competition in India was counting their pennies and spending just what was needed to keep abreast of changing legislation, Cooper Corporation went the whole hog and produced a veritable engineering marvel. Now this engine has set a benchmark for the others to follow.

Once the engine was tested and validated, the engine plant was also ready to be commissioned. The detailed engineering and construction was carried out by Precision Automation and Robotics India of Pune. The team was led by

Dr Ranjit Date, Managing Director and Govind Oza was leading several teams connected with equipment design, layouts, detailed machinery and equipment design, material handling systems, electronic systems etc.

The brief given to them was four-fold:

a)The manufacturing line should be world-class, elegant with best use of technology to ensure satisfactory integration of the materials, design and components.

b)The emphasis would be on the state-of-the-art loading and unloading devices, clamping forces and special machines to ensure the wholesomeness and integration of the Ricardo design with the best engine components and aggregates made by Cooper and their vendors.

c)Cleanliness and a high level of protection from air laden contamination using modern air filtration systems in the ventilation provided in specific areas of assembly.

d)A common rail diesel injection that is a unique and priceless device for successful electronic engine management. This calls for surgical cleanliness in the storage, assembly and handling of the fuel injection system. For this purpose a high purity enclosure within the highly sanitised assembly hall has been designed and implemented.

This production line combines ergonomics and highly productive manual dexterity to augment the various powered mechanical systems for lifting, moving, clamping and measuring. This production line uses several IPV's (Inline Process Verification System) to make sure that the anufacturing process is carried out as per the Ricardo engineering specifications which are enshrined in the Ricardo engine build manual. At every stage after the manufacturing operations an automatic device is used for checking the integrity in assembly.

This production line is standard in that it has a conventional chain conveyor which is carrying on it the trolleys which are required for each engine. All the components of this engine are stored in kitting trolleys switched adjusted to the main assembly line trolley and have within easy reach the components and checking devices used for the assembly. The DC nut runners and other power tools are proved down from over head pneumatic and electric lines within easy reach they provide the necessary power carefully graduated as per the Ricardo tightening specifications.

The production capacity is 24,000 engines per annum and can easily be doubled to 48,000 when the market demand increases. There is further scope for increasing by robotizing selected assembly operations as and when needed. This flexibility has been built in to the system.

The present production line manufactures two cylinder normally aspirated engines and turbocharged engines for industrial automotive and other applications. The same line produces both normally aspirated and the turbocharged engines.

The exclusive requirements of the turbocharged engine as special piston assemblies, turbochargers and such components are stored and made available at specific locations before the engine goes to receive the exclusive fuel injection equipment for such applications. This equipment fitted in the Delphi room for fuel injection equipment assembly and fitment.

The manufacturing operations are not labour intensive in fact they are not even skill intensive. The requirement of manual dexterity is in fact not necessary in the operation of this production system but the workmen concern have to be thinking creative and able to use modern machines and devices to ensure perfection and integrity in assembly and quality.

That the production line is not labour intensive is borne out by the fact that at full capacity not more than eight workmen will be needed for the manufacturing of these engines. The next engine to be produced by Cooper will be their topline six cylinder diesel engine producing 180 to 308 BHP. This engine is currently undergoing endurance testing and should be launched in the near future. This will be followed by the four-cylinder diesel engine producing 121 to 208 BHP.Both engines will continue in the tradition of the twin cylinder by being compact, fuel efficient and low on emissions.

Today, the twin cylinder engine is being incorporated in Cooper Corporation's own range of gensets and talks are on with some major four wheel manufacturers to use this engine in their new range of vehicles. Cooper also has their own small commercial vehicle rolling out next year fitted with this engine. Again this vehicle will feature an ergonomic design and features hitherto available only in passenger cars.

Cooper believes in the future. As an effective insulation from the vagaries of economic cycles, the company has consistently ploughed back its profits into operations and has invested in the latest state of the art technology. It has taken several measures to promote conservation of resources like installation of voltage stabilisers, automatic power correction panels, energy efficient light fittings and 15 windmills. The company has always been technology-driven having won numerous awards and recognition of services by many multinational customers from around the world. Furthermore, the company is ISO 9001:2000 and already certified by TS 16949.

Equipment Financing: Shriram will be one of the biggest retail CE financiers soon

Differentiation in NBFC and bank regulations on income recognition on NPA assets, risk weightage on assets, TDS on repayments, all are some of the major challenges, says Pratap Paode, Chief Executive Officer, Shriram Equipment Finance Company.

Equipment Financing: Widening the Net

CE financing has definitely picked up and has registered a growth of 20 per cent over last year. Though the industry has not touched the peak levels of 2007-08, it expects to end the 4th quarter on a high and continue the growth story in 2011-12.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com